This post will provide you with the required material to understand How To: Complete Stays And Staybolt Questions. Having a solid understanding of this material will provide you with greater success on your 2A1 examination.

All referenced page numbers are from the 2007 ASME Boiler & Pressure Vessel Code

We Will Cover The Following

- How to calculate the required area of stays or staybolts

- How to calculate the required area in diagonal stays

- Review and provide variable definitions for formulas provided in the Boiler & Pressure Vessel Code, along with derived formulas to make calculations easier to complete.

- Review practice questions for how to complete stays and staybolt calculations

Formula

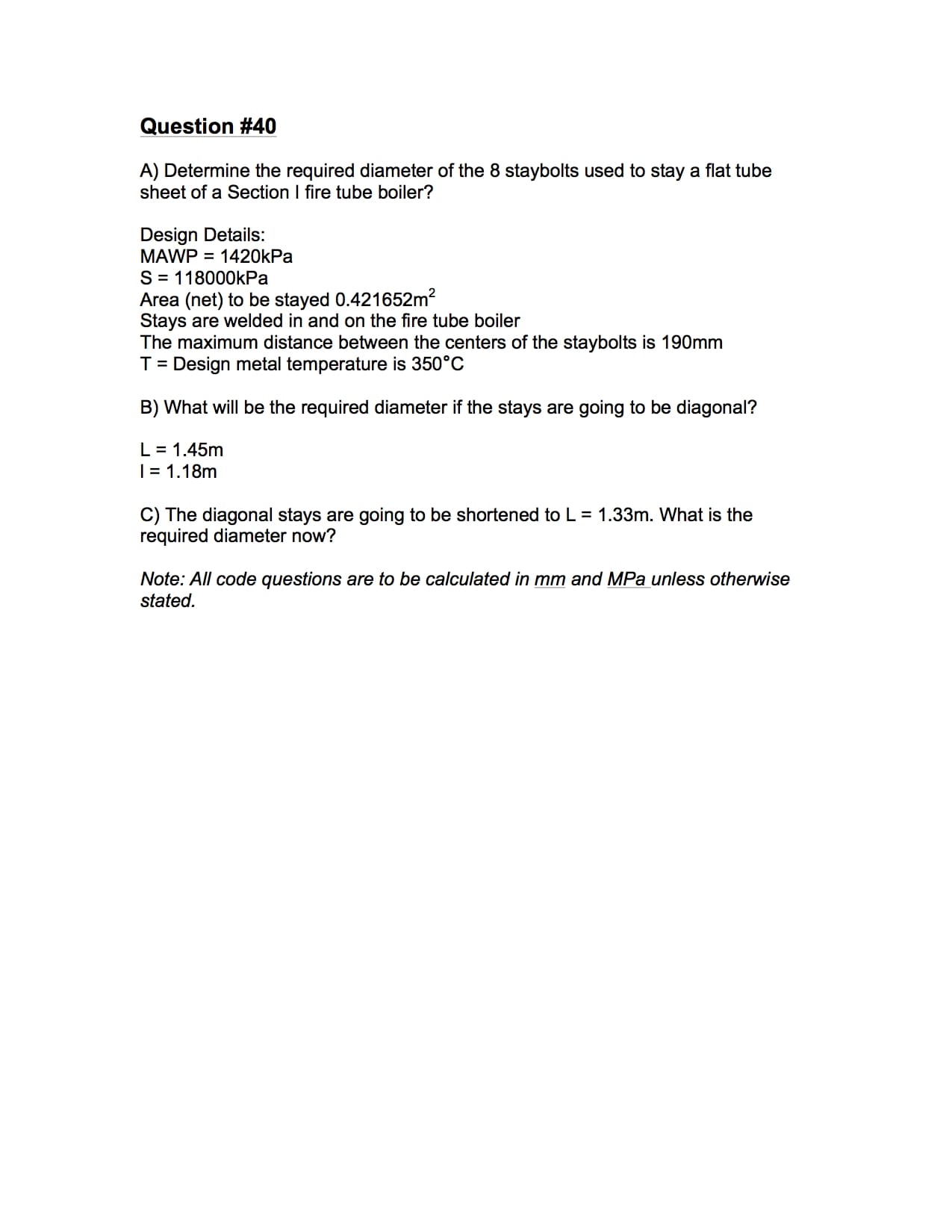

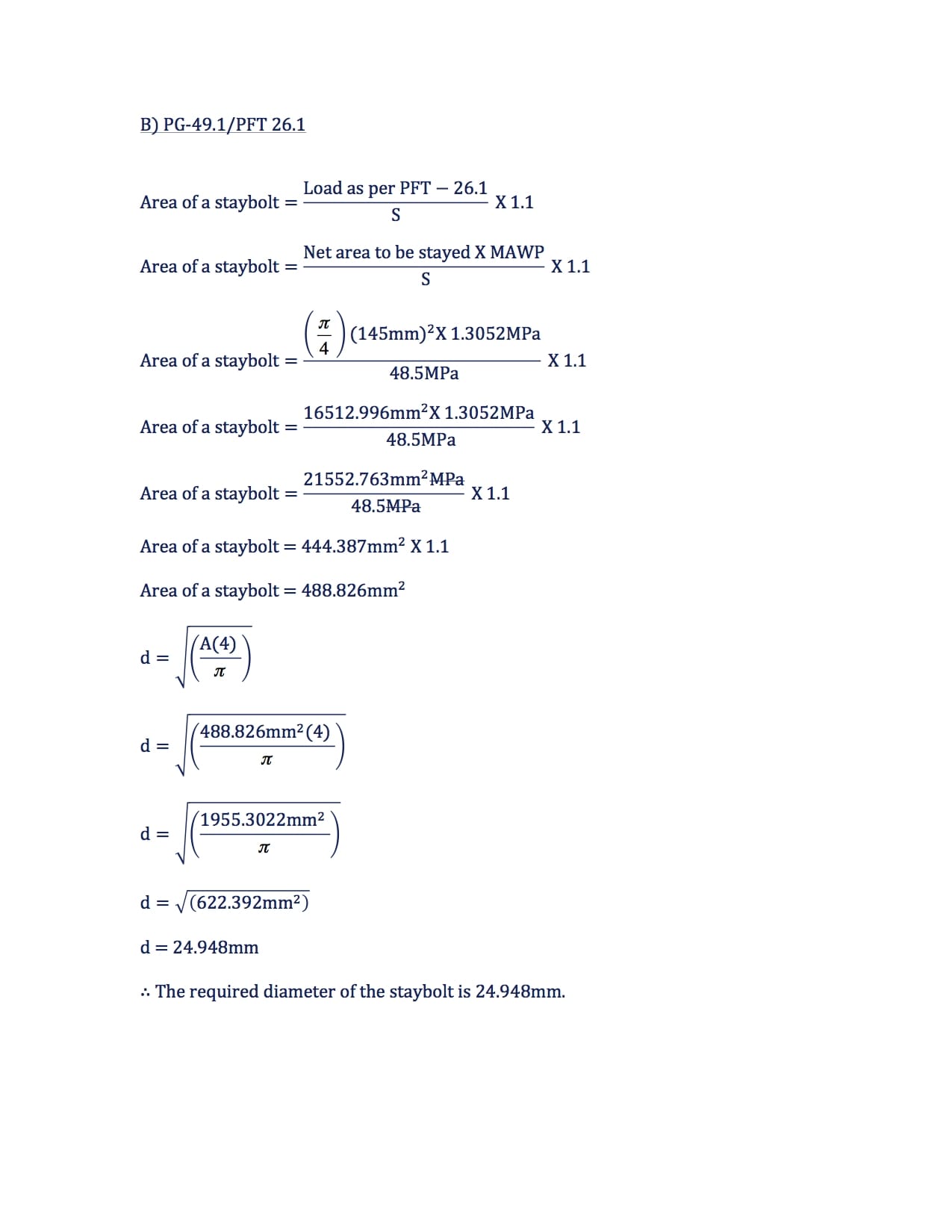

Area Stays Staybolts PG-49.1

![]()

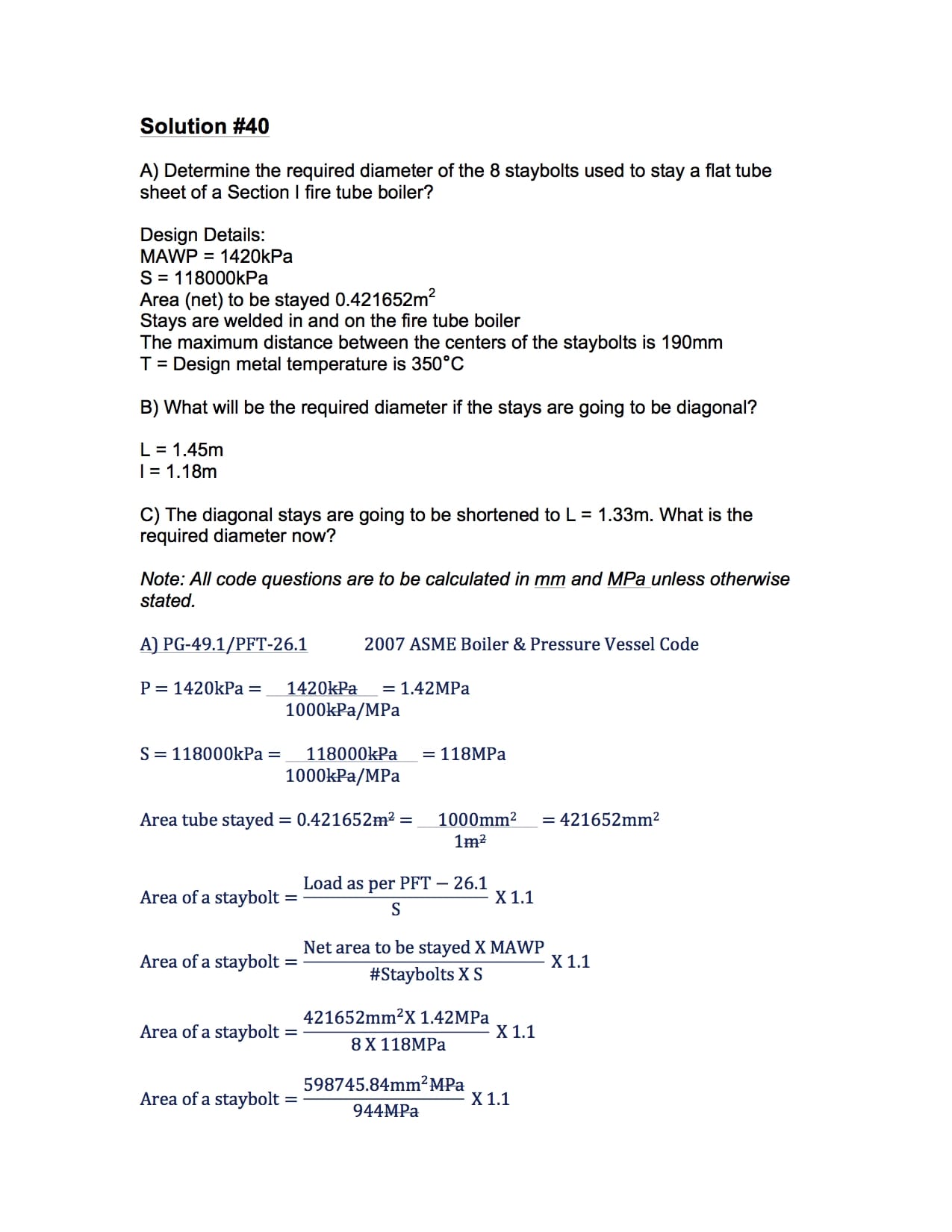

Area Stays or Staybolts PFT-26.1 Requirements Included

![]()

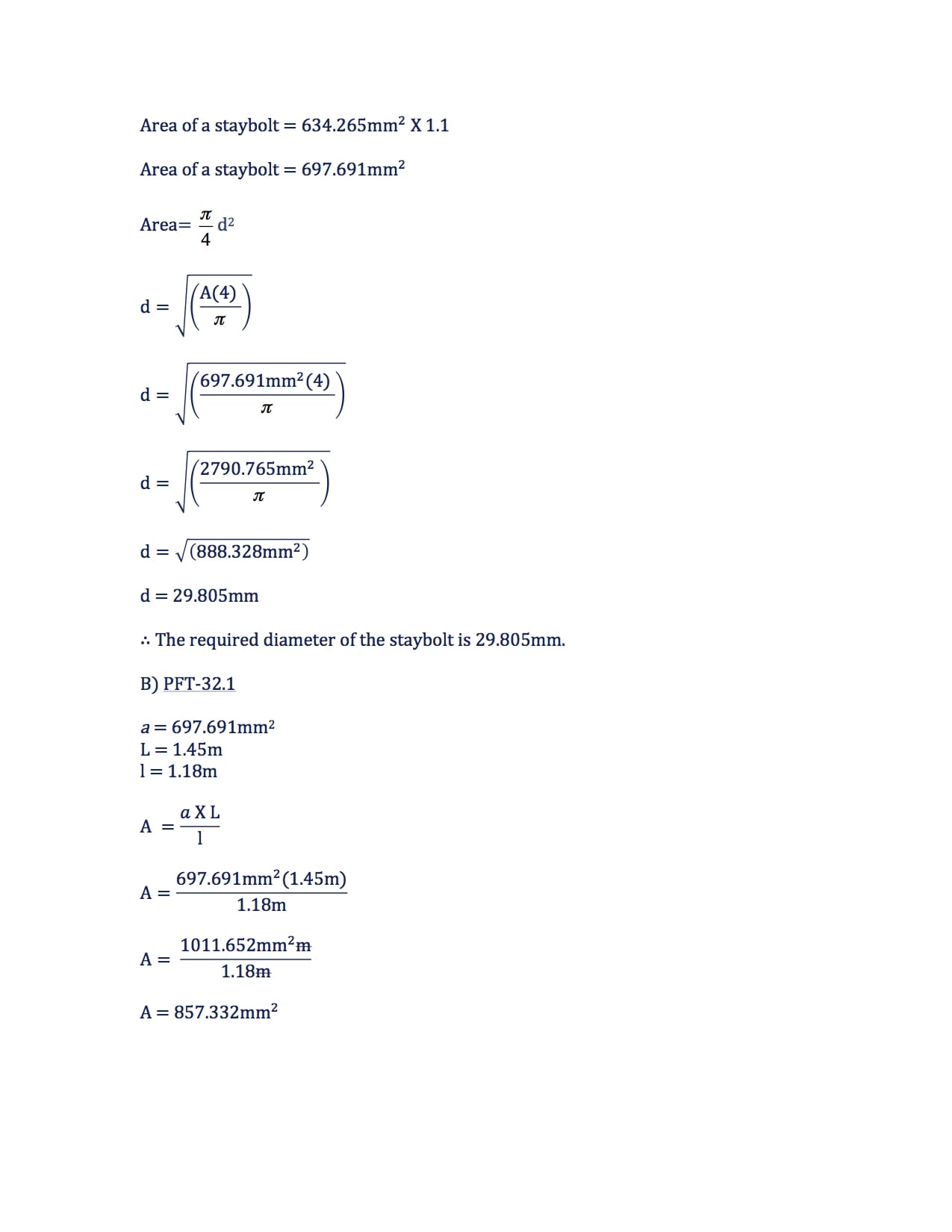

PFT-32.1 Stresses In Diagonal Stays

![]()

PG-46.1 Stayed Surfaces MAWP

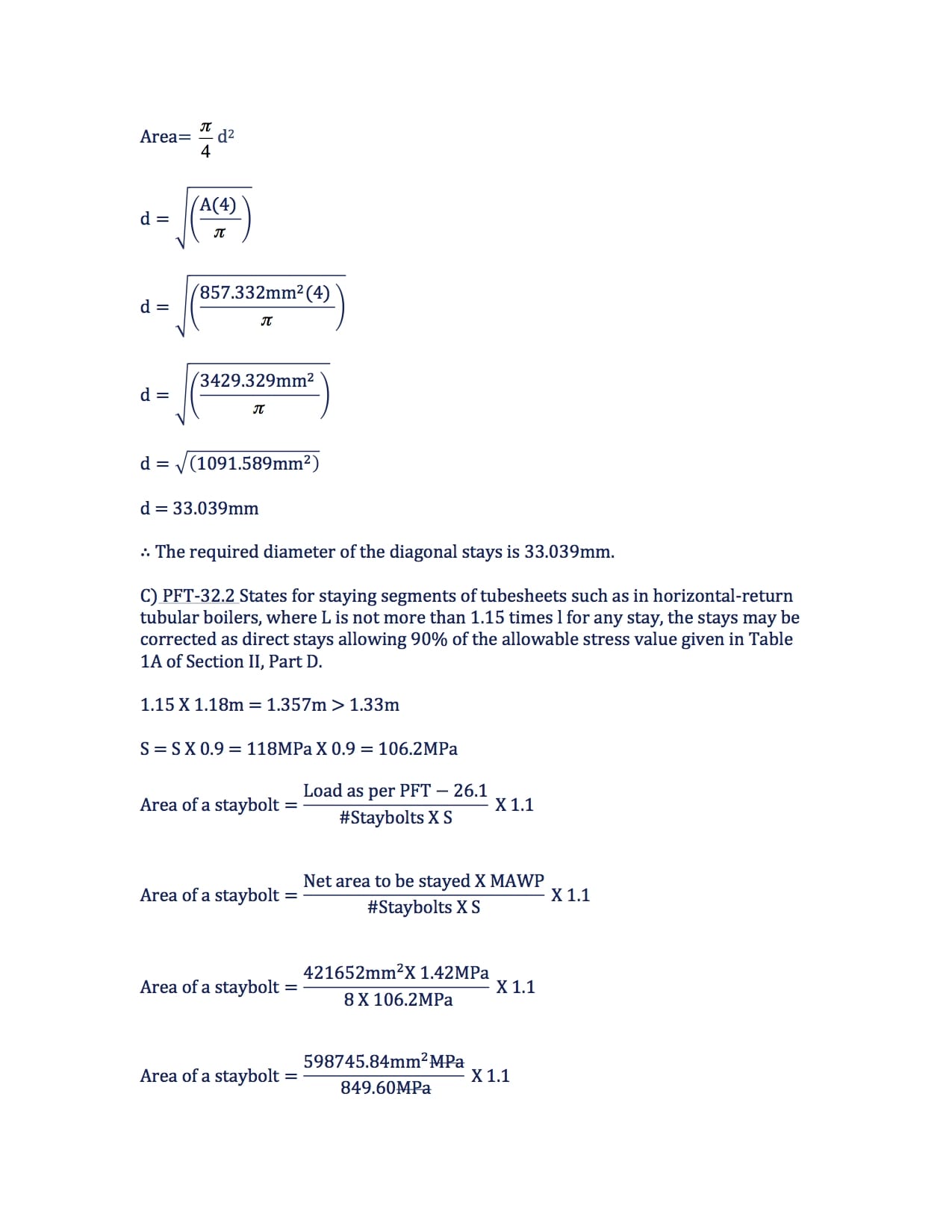

Area Of Circle Using Diameter

![]()

Page 7 Academic Supplement

The above transposed formula to determine the diameter from the area of a circle is not provided in your Academic Supplement

Area Of Circle Using Radius

![]()

Page 7 Academic Supplement

The above transposed formula to determine the radius from the area of a circle is not provided in your Academic Supplement

Formula Variables

Area Stays or Staybolts PFT-26.1 Requirements Included

![]()

The variables used in the formula provided above are defined in PFT-26.1 on page 97

Net Area = Total area of stays or staybolts

MAWP = Maximum allowable working pressure

Staybolts = Number of stays or staybolts

S = Maximum allowable stress value given in Table 1A of Section II, Part D, psi (MPa)

PFT-32.1 Stresses In Diagonal Stays

![]()

The variables used in the formula provided above are defined in PFT-32.1 on page 100

A = Sectional area of diagonal stay

a = Sectional area of direct stay

L = Length of diagonal stay as indicated in Fig. PFT-32

l = Length of the line drawn at right angles to boiler head or surface supported to center of palm of diagonal stay, as indicated in Fig. PFT-32, in. (mm)

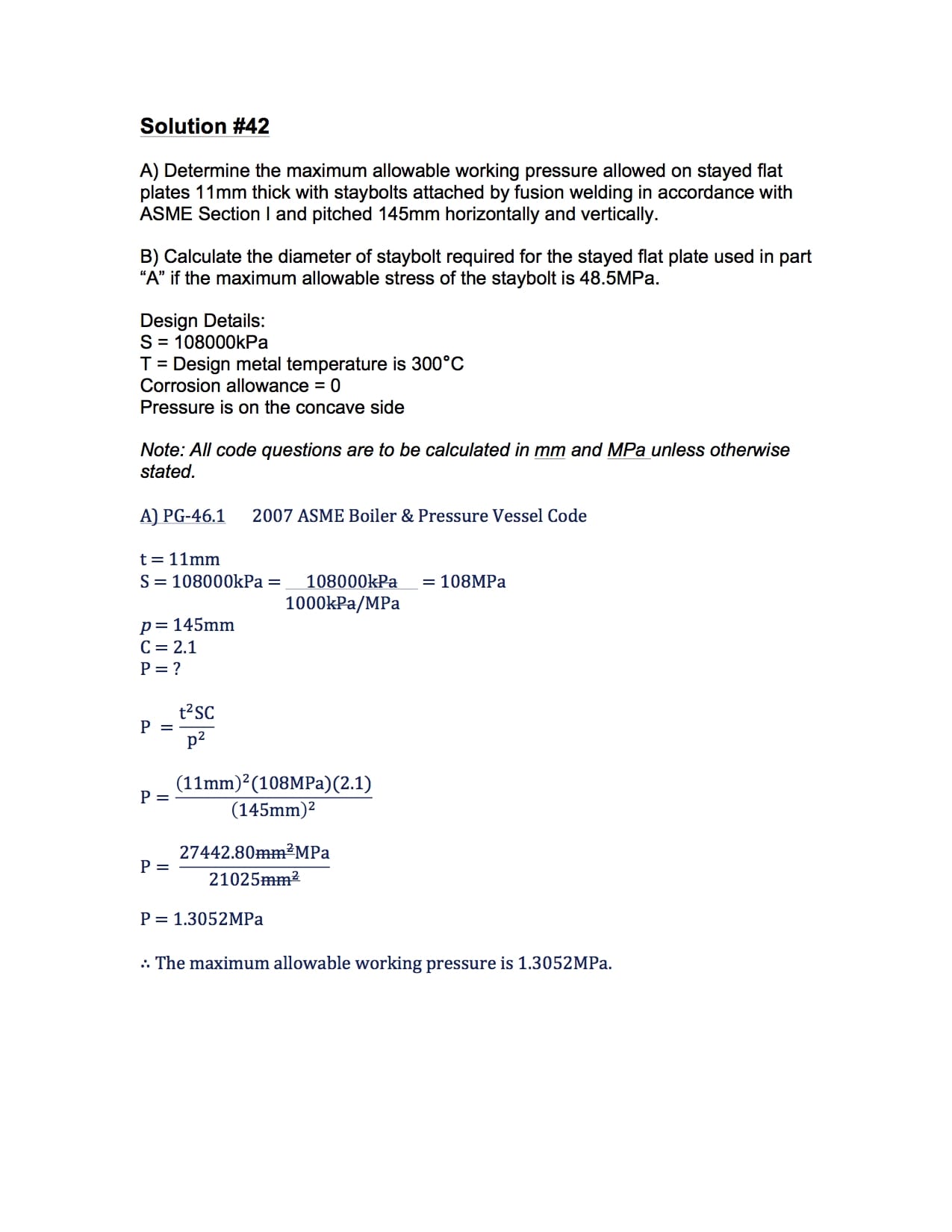

PG-46.1 Stayed Surfaces MAWP

The variables used in the formula provided above are defined in PG-46.1 on page 26/27

C = 2.1 for welded stays or stays screwed through plates not over 7/16 in. (11mm) in thickness with ends riveted over

= 2.2 for welded stays or stays screwed through plates over 7/16 in. (11mm) in thickness with ends riveted over

= 2.5 for stays screwed through plates and fitted with single nuts outside of plate, or with inside and outside nuts, omitting washers

= 2.8 for stays with heads not less than 1.3 times the diameter of the stays screwed through plates or made a taper fit and having the heads formed on the stay before installing them, and not riveted over, said heads being made to have a true bearing on the plate

= 3.2 for stays fitted with inside and outside nuts and outside washers where the diameter of washers is not less than 0.4p and thickness is not less than t

P = Maximum allowable working pressure, psi (MPa)

p = Maximum pitch measured between straight lines passing through the centres of the staybolts in the different rows, which lines may be horizontal and vertical, or radial and circumferential, in (mm)

S = Maximum allowable stress value given in Table 1A of Section II, Part D, psi (MPa)

t = Minimum thickness of plate, in. (mm)

Area Of Circle Using Diameter

![]()

The above formula can be found in page 7 of your Academic Supplement, the variable definitions are not provided.

Area = Area of circle

Pi Symbol = 3.141592654

d = Circle diameter

Area Of Circle Using Radius

![]()

The above formula can be found in page 7 of your Academic Supplement, the variable definitions are not provided.

A = Area of a circle

Pi Symbol = 3.141592654

r = Circle radius

[table id=1 /]

How To: Complete Stays And Staybolt Questions

Note: All code questions are to be calculated in (mm) and (MPa) unless otherwise stated. Convert accordingly and properly before the calculation.

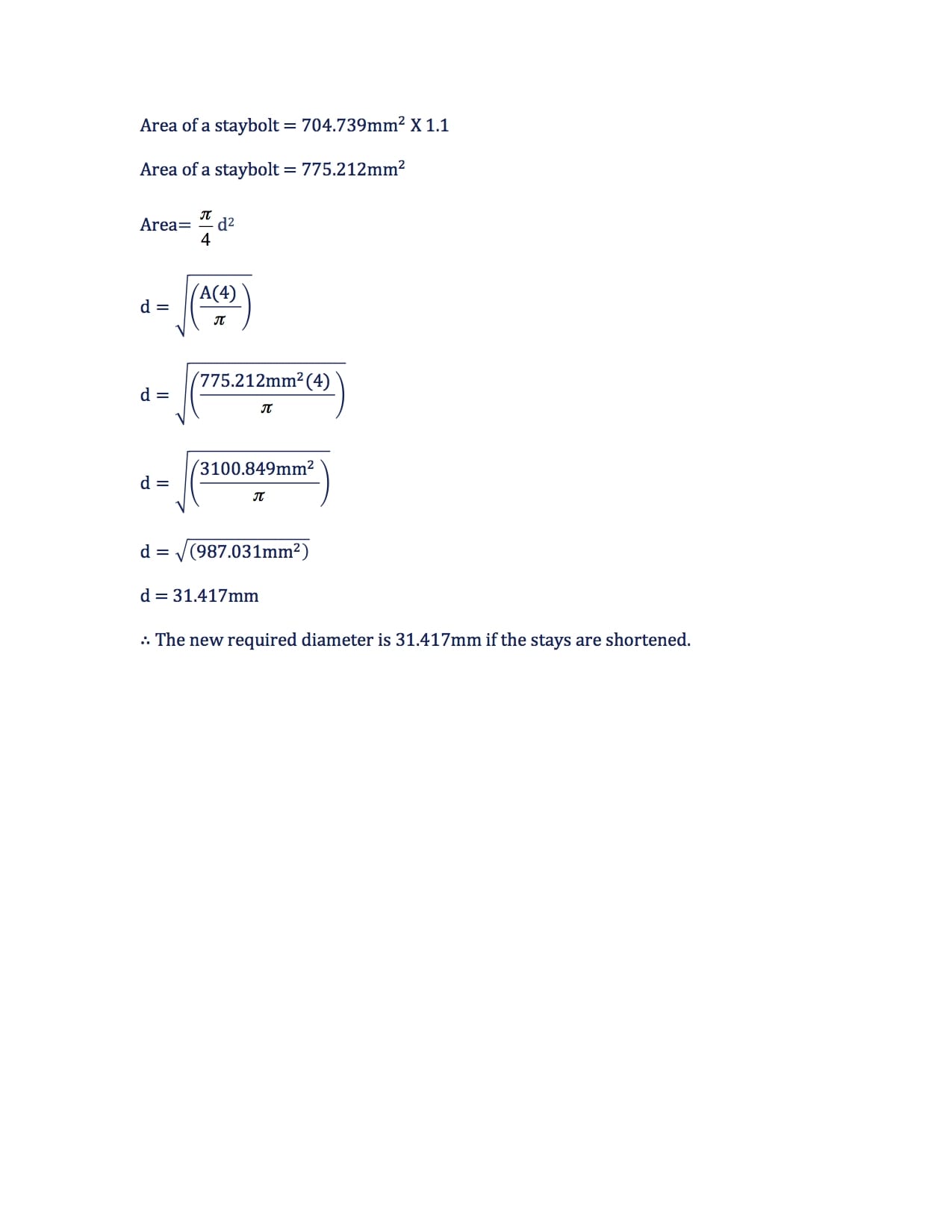

Question #40

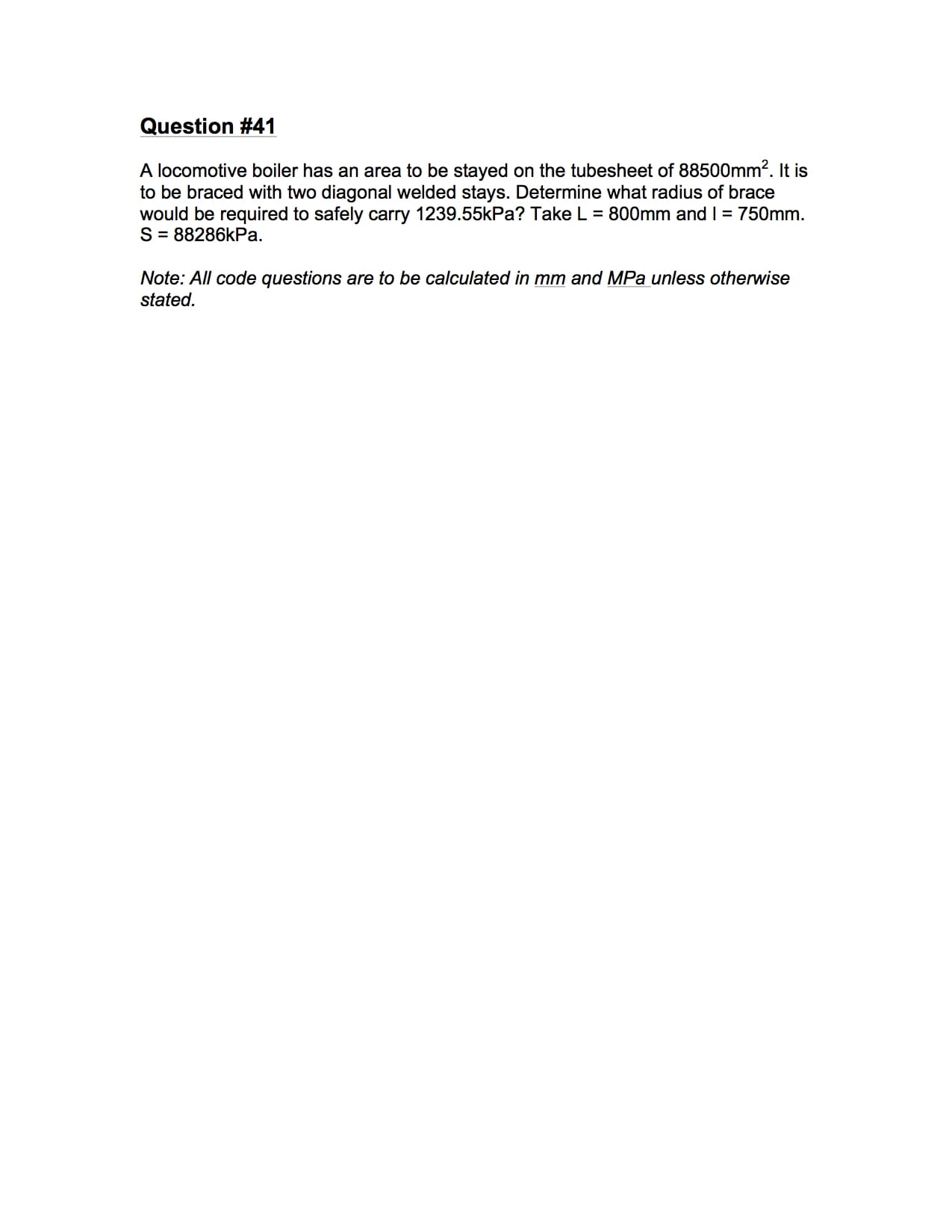

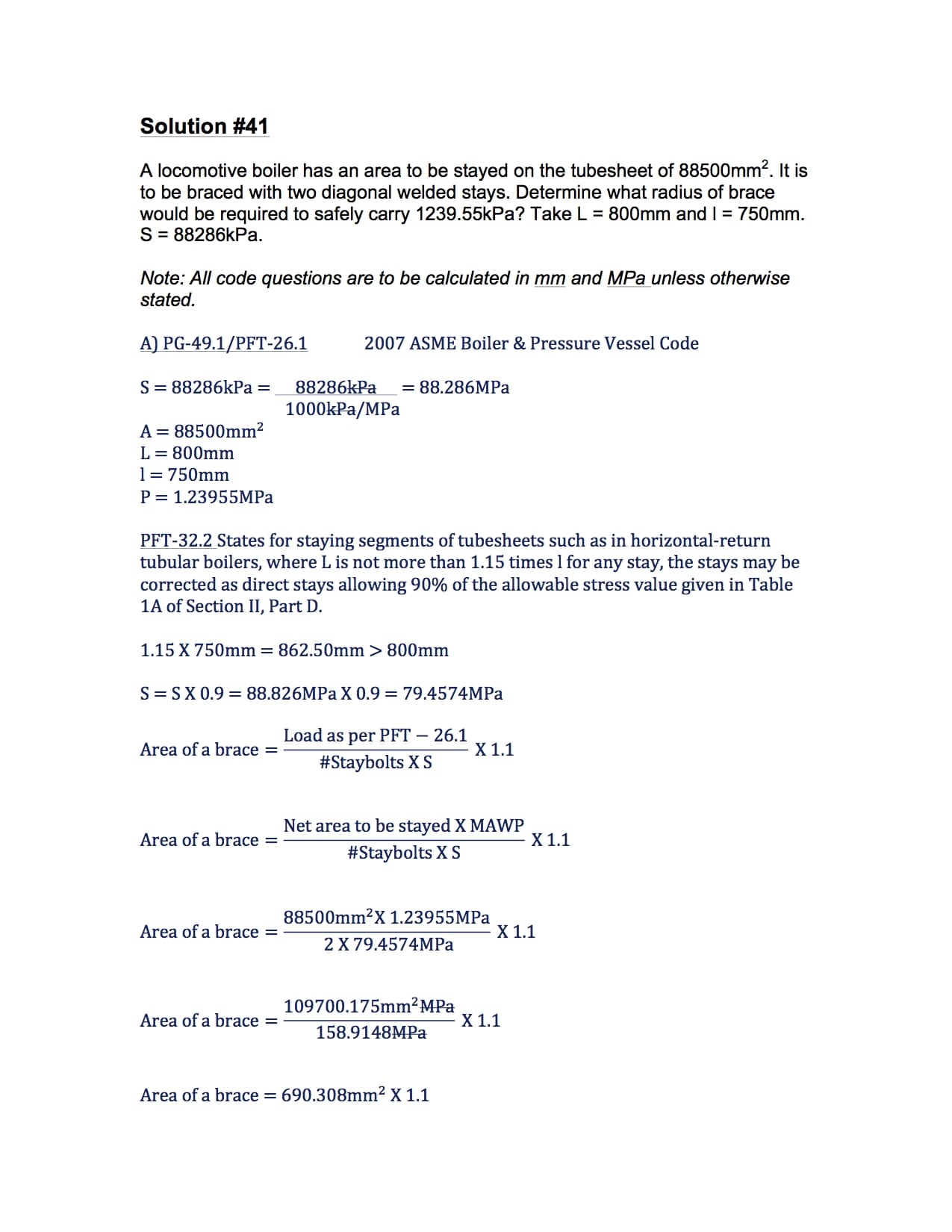

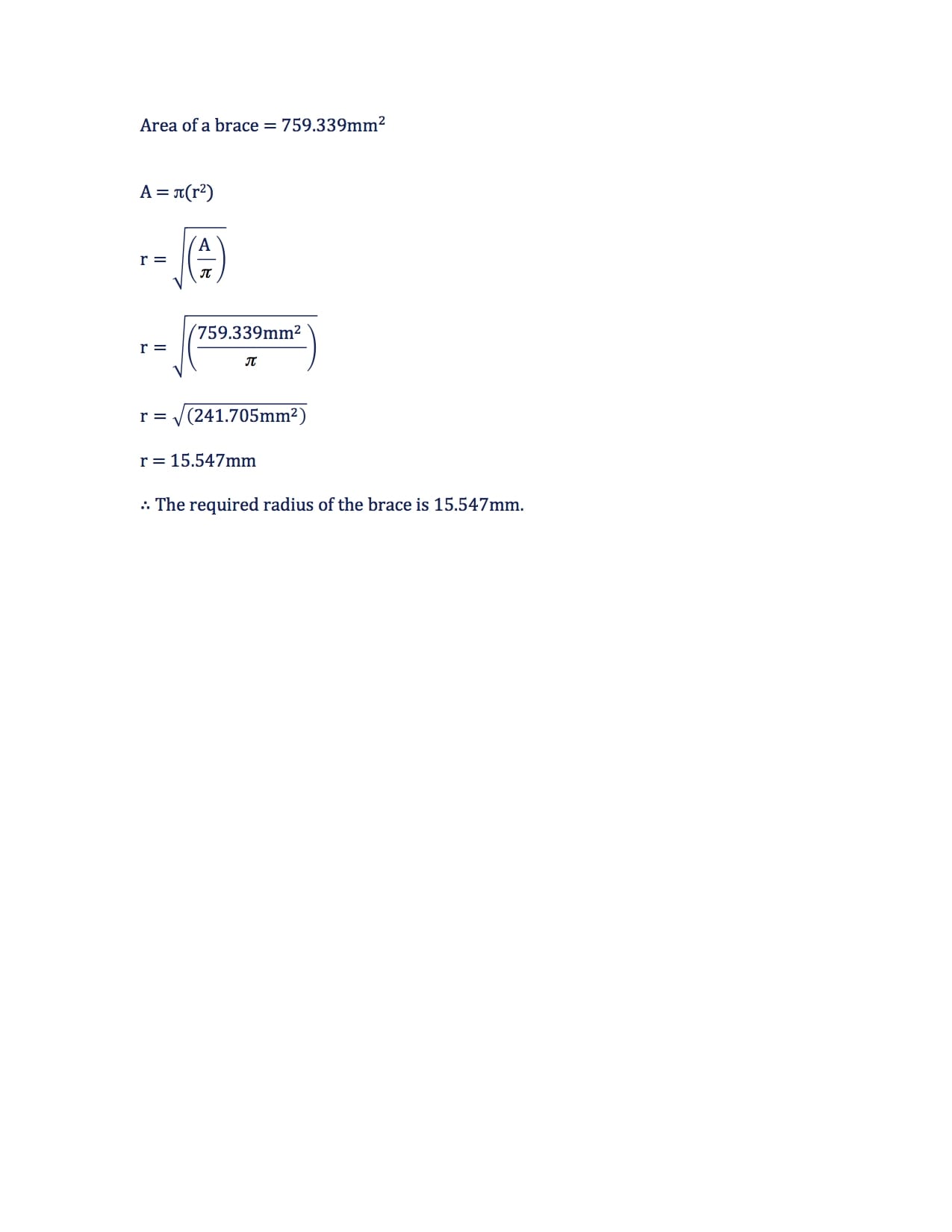

Question #41

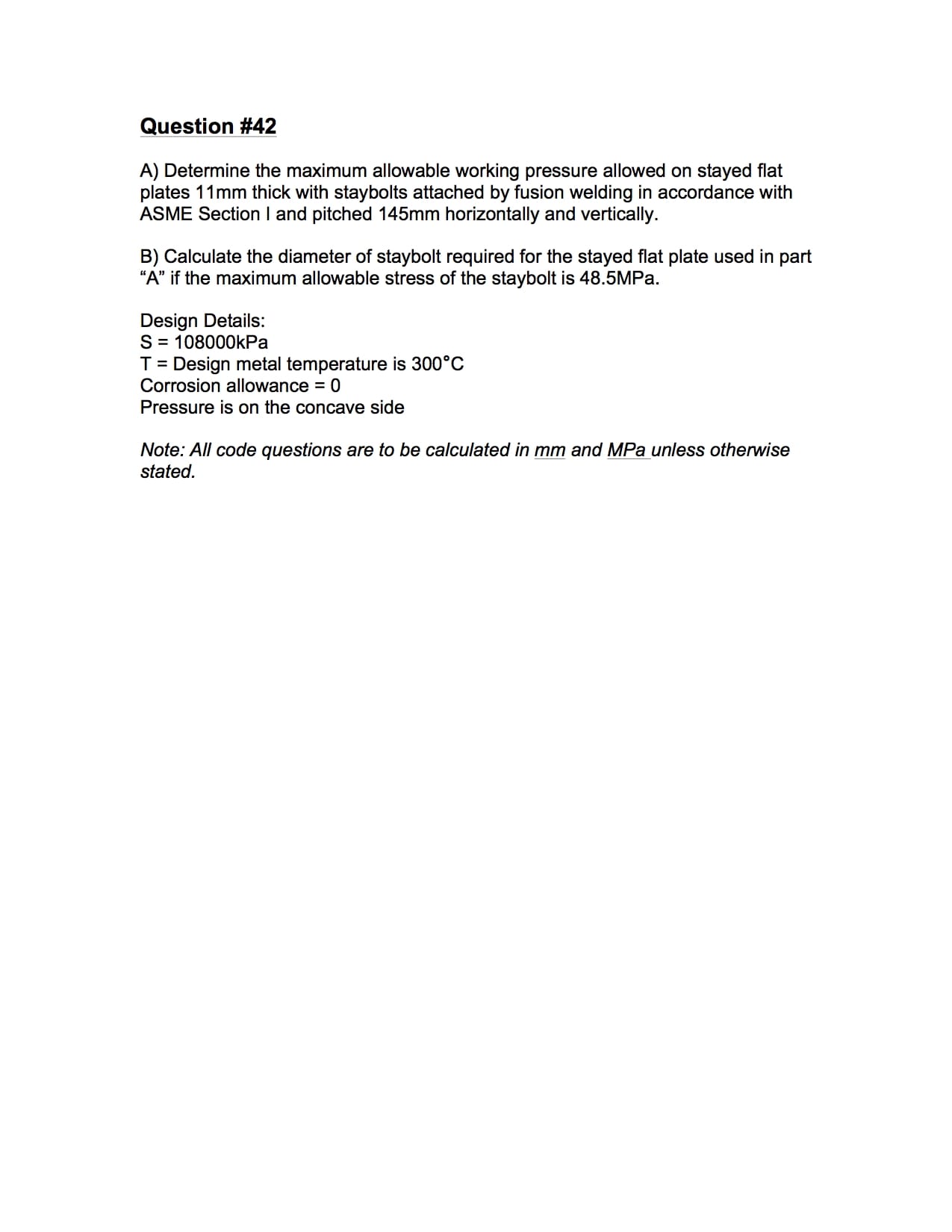

Question #42

SUMMARY: How To: Complete Stays And Staybolt Questions

Did the examples provided helped you understand How To: Complete Stays And Staybolt Questions?

Have you followed Power Engineering 101 on Facebook or Twitter?

Have a great weekend.

Power Engineering 101